PCB Layout with Eagle

Higher Education and Research Infrastructure

Welcome to the comprehensive guide on PCB layout with Eagle provided by Social Service of America, your go-to resource for community and society initiatives in the field of philanthropy.

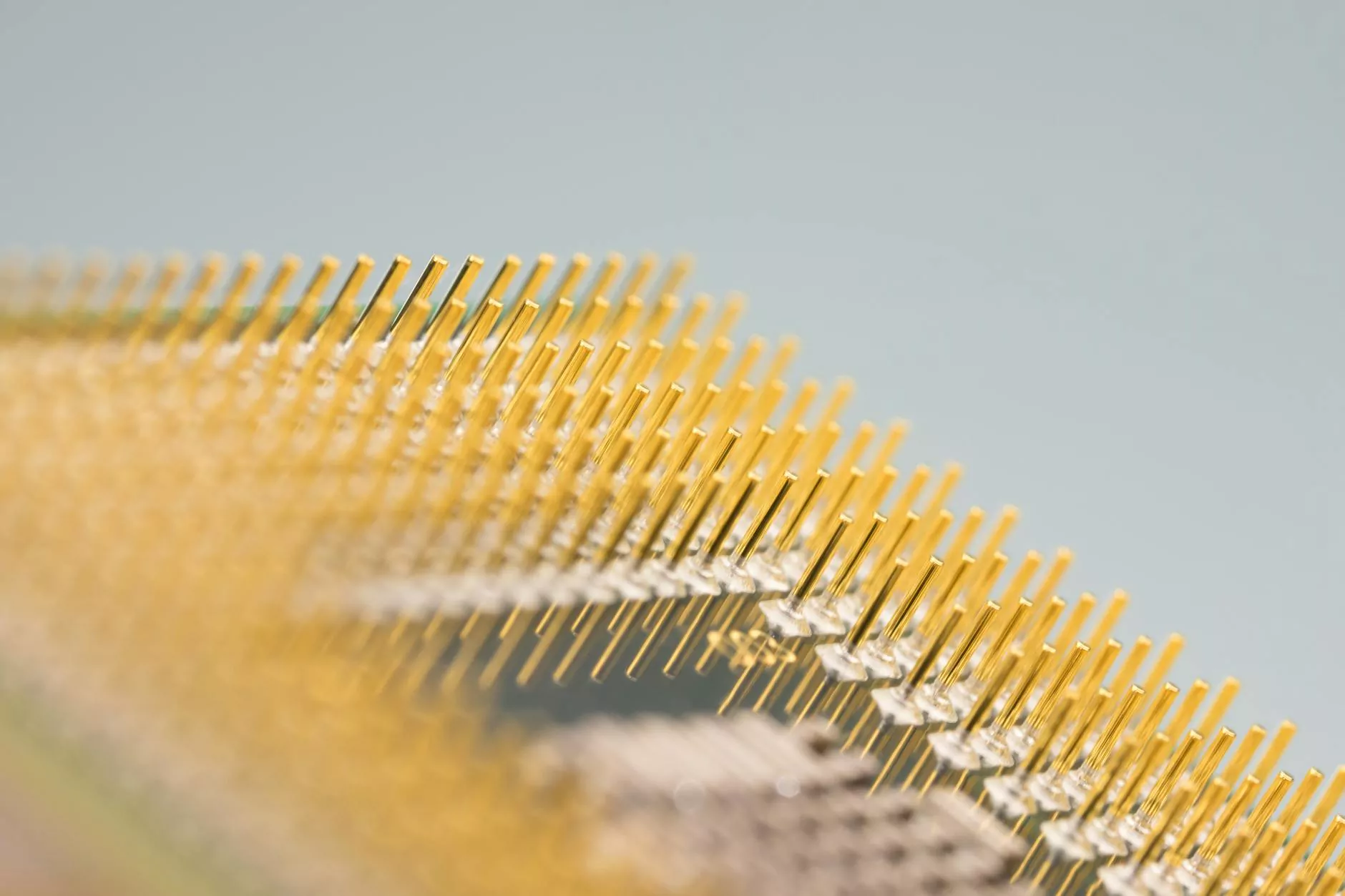

Introduction to PCB Layout

PCB layout plays an integral role in the design and manufacturing of printed circuit boards (PCBs). A well-designed layout is crucial for ensuring optimal circuit performance, reliability, and functionality. In this guide, we will explore the intricacies of PCB layout using the industry-standard software, Eagle.

The Importance of PCB Layout

A well-executed PCB layout can significantly impact the overall performance and functionality of electronic devices. It involves placing electronic components, connectors, and traces on a PCB to create an efficient and reliable circuit. With Eagle, mastering the art of PCB layout becomes much more accessible.

Getting Started with Eagle

Eagle is a popular PCB design software developed by Autodesk. It offers a range of powerful features, making it suitable for both hobbyists and professionals. In this section, we will walk you through the process of getting started with Eagle.

1. Download and Installation

Before diving into PCB layout, you'll need to download and install Eagle on your computer. Visit the official Autodesk website, locate the Eagle software, and follow the provided instructions for installation. Once installed, you're ready to start designing PCB layouts.

2. Navigating the User Interface

Eagle's user interface may seem overwhelming to beginners, but with a little guidance, it becomes easier to navigate. Familiarize yourself with the various toolbars, menus, and panels. Understanding the interface is the first step towards creating professional PCB layouts.

3. Designing Your PCB Layout

When designing a PCB layout, it's essential to consider various factors such as component placement, signal integrity, thermal management, and manufacturing constraints. Eagle provides a user-friendly environment to assist you in making informed decisions during the design process.

Start by creating a new project and defining your board specifications. Then, add components to your schematic and map them to footprints. Once the schematic is complete, you can create a board layout and arrange the components according to your design requirements.

4. Routing and Traces

Routing refers to the process of creating traces to connect various components on the PCB. Eagle offers an advanced routing engine that enables efficient, error-free trace routing. It allows you to define trace widths, clearance rules, and other parameters to ensure optimal signal integrity and reliability.

Consider factors such as high-speed signals, power routing, and signal grounds during the routing process. Ensuring proper signal quality and minimizing noise interference are critical for achieving optimal PCB performance.

5. Design Rule Check (DRC) and Gerber Generation

Before finalizing your PCB layout, it is crucial to perform a Design Rule Check (DRC). The DRC verifies your design against predefined electrical and manufacturing constraints, ensuring compliance with industry standards. Eagle's DRC feature helps detect and resolve potential design flaws before sending the layout for manufacturing.

Once your PCB layout is error-free, you can generate Gerber files, which are essential for PCB fabrication. Gerber files provide manufacturers with the information required to produce the physical PCB accurately.

Best Practices for PCB Layout

Now that you are familiar with the basics of PCB layout using Eagle, let's delve into some best practices that will help you create efficient and reliable PCB designs:

1. Optimal Component Placement

Placing components strategically on the PCB can significantly impact the overall performance. Group similar components together and keep signal paths as short as possible to minimize signal degradation and interference. Consider factors such as thermal management, component accessibility, and manufacturing constraints while placing components.

2. Ground and Power Planes

Creating dedicated ground and power planes within your PCB layout helps minimize noise and interference. These planes provide a low impedance return path for high-speed signals, ensuring signal integrity. Properly distributing ground and power connections across the board is crucial for maintaining stable and reliable power distribution.

3. Signal Integrity and EMI Considerations

Signal integrity plays a crucial role in high-frequency PCB designs. Be mindful of signal paths, trace lengths, and impedance matching to minimize signal loss and reflections. Implement EMI shielding techniques, such as proper ground plane utilization, and by placing components sensibly to reduce electromagnetic interference.

4. Design for Manufacturability

Designing PCB layouts that are manufacturable with ease is essential. Consider manufacturing processes such as soldering, assembly, and testing while designing your PCB. Ensure proper clearances, pad sizes, and routing restrictions are in line with the capabilities of the chosen manufacturer.

Conclusion

Mastering PCB layout with Eagle opens up a world of possibilities for designing efficient and reliable circuits. By following the best practices outlined in this guide, you can create PCB layouts that meet industry standards and surpass expectations.

Remember, practice and continuous learning are key to becoming a proficient PCB layout designer. Keep exploring new techniques, stay updated with the latest industry trends, and never shy away from seeking help and guidance when needed.

Social Service of America proudly presents this comprehensive guide in the field of PCB layout with Eagle to assist you in your journey towards becoming a skilled PCB designer. Start designing with confidence, and unlock your potential in the world of electronics!